In short:

1. WHICH EDITING PROGRAM SHOULD I USE?

Use Adobe Indesign, Adobe Illustrator, Corel Draw.

2. WHAT TYPE OF FILE DO I SEND TO THE PRINTER?

Submit Acrobat 5 (pdf 1.4) or Acrobat 6 (pdf 1.5) PDF files

3. EDITING AND LAYOUT RULES FOR PRINT:

A. Image resolution – 300 dpi

B. All elements to be CMYK

C. Bleed is mandatory (outer 3 or 5 mm and inner 3-10 mm)

D. Text Color (Black K100%, Gray K20-80%)

E. Thin lines at least 0.07-0.2 mm thick

F. The covers are sent mounted (spread), and the pages separately (single pages, not facing pages!), with bleed on the outside.

1. What editing program should I use?

You must only edit and layout in a program compatible with typographic technical requirements, such as:

- Adobe Indesign – recommended for works with several pages such as: books, catalogs, magazines, etc.

- Adobe Illustrator or Corel Draw - recommended for works with few pages: flyers, leaflets, labels, stickers, posters, business cards, etc.

Adobe Photoshop or other image editing programs can be used to a limited extent on single-page works where you have predominantly a photographic image. An example would be a poster with a photo as a background. Preferably, however, it should be used for color processing of images, collages or specific effects.

Please keep in mind that there is a big difference between the operation of printing or copying a document on an office printer/multifunctional and the professional process of printing in a printing house, which is much more complex and requires that the submitted file respect certain strict, mandatory technical requirements. These technical requirements They can NOT be obtained by editing the document in an Office-type program such as Word, Excel, Power Point, etc., even if at the end you export by generating a PDF file! We cannot use this PDF as such. However, if you have such a file and need to print it as such, you need to embed the fonts or make them curves and convert the colors to CMYK.

2. What type of file do I send to the printer?

For printing, it is best to send Acrobat 5 (pdf 1.4) or Acrobat 6 (pdf 1.5) PDF files. You can do this setting in Acrobat Distiller. Choose Press Quality and then from Settings / General / Compatibility choose Acrobat 5 or 6. Under certain reservations, the PDF X-1a setting is also valid.

After you have finished the graphic layout in the editing program intended for printing of your choice, export by selecting the option you saved in Acrobat Distiller. In this way you ensure that you get a file that corresponds to the technical requirements of the typography. However, it will still be necessary to respect the editing and layout rules from point 3. Do not use color profiles for export.

Do not check crop marks, scales or other information. Only mark bleed if you used beed.

Can I send JPG or TIFF files?

Yes, you can send for simple work such as flyers, making sure the document is CMYK; and, if it's JPG, have minimal compression.

However, you must accept the fact that in certain situations you will not benefit from all the advantages of a PDF file, and the result may not be at the same level of quality.

3. Editing and layout rules for print

This is a set of minimum mandatory rules.

A. Image resolution – 300 dpi

The optimum resolution for offset and digital printing is 300 dpi. Above this resolution, the print quality will not be better. Below this resolution, poorer image quality begins to be perceived:

- between 250 – 300 dpi – very small differences, good quality

- between 200 – 250 dpi - a lack of clarity, lack of details, average quality is perceived

- between 150 – 200 dpi – the lack of details is perceived and the image starts to become pixelated, poor quality

- between 100 – 150 dpi – pixelated image, unpleasant, very poor quality

- between 72 – 100 dpi - intensely pixelated image, without details, annoying and hard to accept

Beware of images downloaded from the Internet that are usually 72 dpi! An image that originally had a poor resolution will not improve using the "resample" option!

B. All graphics to be CMYK (or Pantone if desired) but not RGB!

Offset printing specifically requires fully CMYK files, without any RGB elements; otherwise the colors will come out altered. It is also recommended for digital printing that you convert all elements to the CMYK color model for full color control and, above all, to ensure that you get the same color results every time on possible reprints. "All elements" means: bitmap images, texts and any other graphic elements such as lines, borders, color surfaces, vector designs, etc.

We won't go into details about Pantone colors here; please, if you want to use them, ask us for information.

NOTE: When final exporting to a PDF file, if you choose the PDF 1.4, PDF 1.5 or PDF X-1a option, ensure that all elements in the file are automatically converted to the CMYK color model and, if applicable, Pantone .

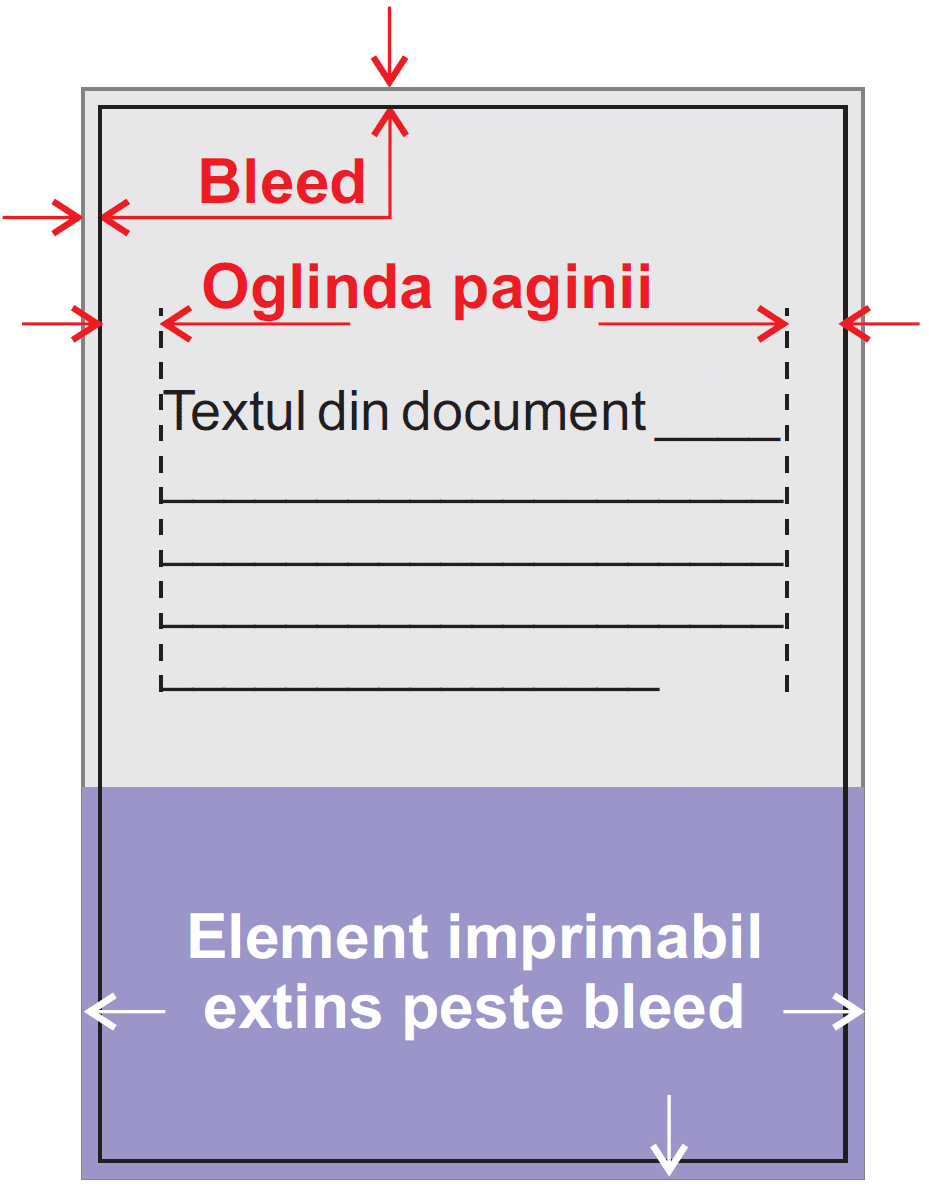

C. Bleed must always be found in the file intended for typography

Practice shows us that the notion of bleed is more difficult for beginners to understand; however, bleed is indispensable, not optional, and must be well understood and applied correctly.

Bleed is an extension of the surface of the finished page format, 3-5 mm, applied all around. For example, a page with the finished format A4, 210 x 297 mm, will have, with a bleed of 5 mm, the raw format of 220 x 307 mm. The extra 3-5 mm area called bleed will be cut in the process of finishing the work, and you will receive the order in the finished format.

Bleed is required when you have at least one printable element that is placed at the edge of the page. That element or elements that go to the edge must also be extended to the surface of the bleed. The exception is if you have white margins on all pages, without print, as in text books, where bleed is not necessary.

Bleed size:

- for single-page or single-sided jobs, so two pages (flyers, posters, labels, stickers, business cards, etc.) a bleed of 3 mm is sufficient

- for multi-page works that require binding (brochures, books, catalogs, calendars, diaries, etc.) 5 mm bleed is required, including covers

Extend photographic images or graphics, colored backgrounds, lines, etc., over the entire surface of the bleed. Bleed should only stay white where you have white at the edge of the page!

Some editing programs will also apply bleed to the spine of the page when exporting to PDF, which is not wrong, although it is not necessary. The file thus obtained is technically good for printing.

Just as the bleed is necessary, so is respecting the mirror of the page (the inner bleed). Important elements (texts, logos, colon numbers, etc.) must not be closer than 3 mm to the edge of the page. And for books, magazines that are paperbacks, they must be 1 cm from the edge towards the spine. Same with covers 2-3.

D. Black or gray text color composition

You must ensure that the text is converted to the CMYK color model. For best results we recommend that:

- black text let C=0%, M=0%, Y=0%, K=100%.

- gray text let C=0%, M=0%, Y=0%, K= values between 20-80%.

Colored text will obviously have various CMYK components.

Be careful when importing black text from other editing programs such as Word into the editing program intended for printing. The text will be imported RGB, and when converted to CMYK it will be black with values from all CMY components and you will need to redefine it C=0%, M=0%, Y=0%, K=100%.

E. Minimum thickness of lines (of solid color, respectively of combined colors)

Solid color lines must be at least 0.07mm thick!

Full color means 100% of CMYK base colors (black 100% or cyan 100%, etc.)

Lines in color percentages must be a minimum of 0.2 mm. Otherwise, the lines will come out with breaks or varying thickness due to rasterization. The lower the color percentage, the thicker the line must be to come out evenly.

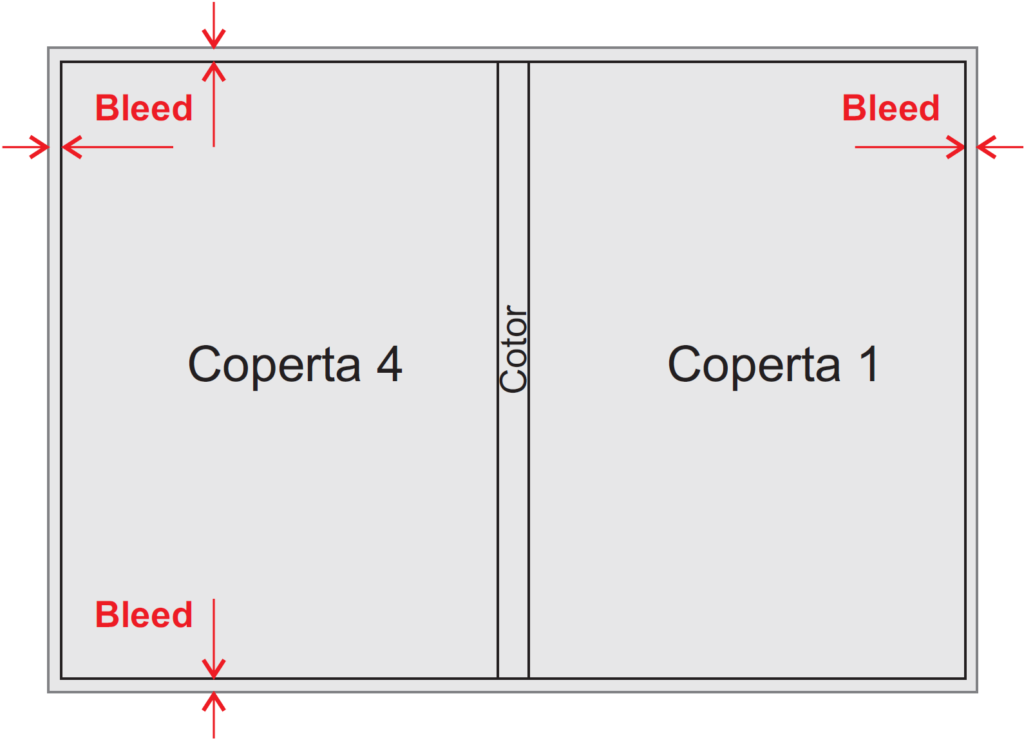

F. Layout of covers and pages

The covers are delivered to the printing house mounted, as follows:

- the outer covers, from left to right: COVER 4 – SPINE – COVER 1

- inner covers: COVER 2 – SPINE (WHITE) – COVER 3

Don't forget the 5mm bleed that needs to be put around the mounts above!

The inner pages are delivered unassembled, SINGLE PAGES, not facing pages! In other words, the inner pages will be delivered in a single file containing all the pages, one after the other, INCLUDING ALL WHITE PAGES, cover pages and end pages (if any). Please ask us for the number of pages in the volume. Depending on the size of the letterpress and book, you will need to have a total number of inside pages in multiples of 8, 12, etc.

Final specifications

This information is the minimum necessary to be respected for the professional pattern. Printmaking is a job in itself, which requires knowledge and experience; in order to obtain the best results, we recommend clients to collaborate only with graphic designers experienced in the relationship with typographies.

For other works, such as those that require stamping operations, that use Pantone colors or complex or atypical works, Please contact us and we are at your disposal with all the information you need to get the best results in print.

Thank you for your interest!